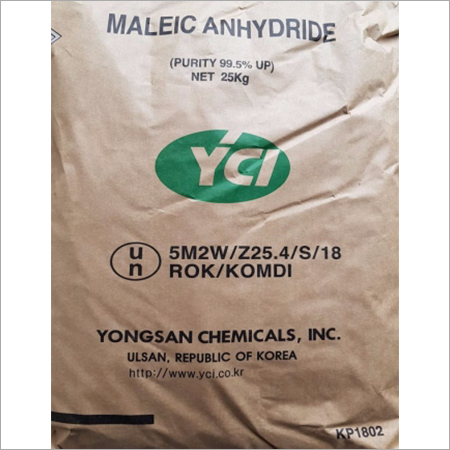

Maleic Korea

MOQ : 500 Kilograms

Maleic Korea Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Delivery Time

- 10-15 Days

About Maleic Korea

Technical details

| Property | Test Method | Unit | Test ruselts |

| Appearannce | White briquet or pastel type | White briquet type | Visual |

| Molten colour (apha) | 20 max | 9 | Jis K 1359 |

| Purity ( Total acid )wt% | 99.5 min | 99.1 | Jis K 1359 |

| Solidificstion pointoC | 52.5 min | 52.6 | Jis K 1359 |

| ASW wt% | 0.001 max | 0.0007 | Jis K 1359 |

| Iron (ppm ) | 1 max | <1 | Absorption spactophotometry |

| Packing Size : 25 Kg | |||

Chemical Profile and Key Features

Maleic stands out due to its high purity, stable crystalline form, and adaptable solubility in various solvents. Its chemical robustness makes it suitable for multiple industrial applications, especially in resin, coating, and plasticizer formulations. Its moderate melting point and longevity further support safe and consistent usage in different manufacturing processes.

Applications and Benefits

In the industrial sphere, Maleic is sought-after for its role in the production of resins, coatings, and plasticizers. These products benefit from Maleics reactivity and stability, enhancing end-product quality. The compounds high purity and solubility increase formulation efficiency, yielding better coatings and more flexible plasticizers.

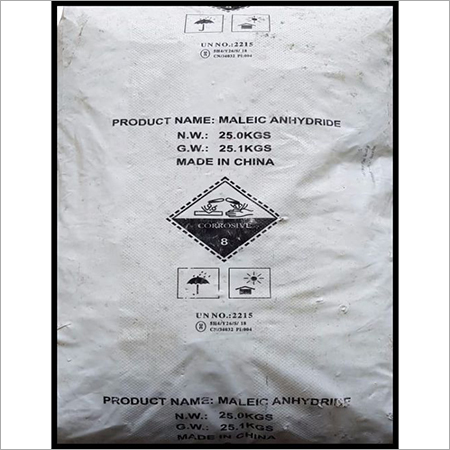

Packaging and Safe Storage Guidelines

Maleic is supplied in 25 kg bags, ensuring straightforward handling and transport. Proper storage is criticalalways keep the product in a cool, dry, and well-ventilated area to prevent degradation. Adhering to these guidelines helps maintain its two-year shelf life and ensures that its quality remains intact for demanding applications.

FAQs of Maleic Korea:

Q: How should Maleic be stored for maximum shelf life?

A: Maleic should be stored in a cool, dry, and well-ventilated area to prevent moisture absorption and degradation, thereby maximizing its shelf life of 2 years.Q: What are the primary industrial applications of Maleic in India?

A: Maleic is predominantly used in the manufacture of resins, coatings, and plasticizers, due to its chemical stability and high purity, making it valuable for industrial production.Q: When is the optimal time to use Maleic after purchase?

A: For best results, use Maleic within its two-year shelf life. Ensure the storage conditions are maintained according to guidelines to preserve its chemical properties during this period.Q: Where is Maleic supplied and distributed in India?

A: Maleic is supplied and distributed by Maleic Korea through authorized distributors across India, ensuring prompt availability for industrial needs.Q: What is the process for using Maleic in resin manufacturing?

A: In resin manufacturing, Maleic is introduced as a raw material, where it reacts with other monomers to form durable and high-performance resins suitable for coatings and plasticizers.Q: What benefits does Maleic offer in coating formulations?

A: Maleics high purity and compatibility with various solvents enhance resin properties in coating formulations, resulting in improved film-forming abilities and long-lasting surface protection.Q: How is Maleic packaged and delivered to customers?

A: Maleic is packaged in sturdy 25 kg bags designed to protect against moisture and contamination, facilitating safe handling and transport to customers throughout India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Maleic Anhydride Category

RYAN INTERNATIONAL

GST : 27ACHPM6120G1ZR

GST : 27ACHPM6120G1ZR

No. 52-D, 'Samrat', Office No:6, Ground Floor,

Sir M. V. Road, Opposite Vishal Hall, Andheri (E), Mumbai - 400069, Maharashtra, India

Phone :08045800071

|

|

RYAN INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry