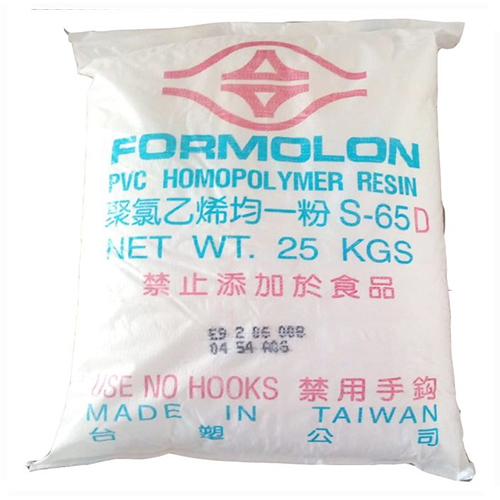

PVC Resin Pipe Grades

MOQ : 1 Piece

PVC Resin Pipe Grades Specification

- Density

- 1.4 g/cm³

- Plasticizer Absorption Value

- 19-21

- Application

- For Pipe Manufacturing

- Form

- Powder

- Particle Size

- 99% Pass 250 Mesh

- Ash Content

- 0.03% Max

- Moisture

- 0.1% Max

- Grade

- Pipe Grade

- Color

- White

- Volatile Content

- 0.20% Max

- Bulk Density

- 0.45-0.55 g/cm³

- Purity

- 99.9%

- K Value

- 65-67

PVC Resin Pipe Grades Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 20-25 Days

About PVC Resin Pipe Grades

PVC resin pipe grade is basically homopolymer resin which is manufactured from vinyl chloride monomers through polymerization process. Light in weight, offered resin is reckoned for its versatile nature as its extensive application can be noticed in different industries. PVC resin pipe grade possesses excellent resistance capacity against damaging effects of water, rust and chemicals. Moreover, it possesses strong electrical insulation characteristics. PVC resin pipe grade is UV protected and it is fire retardant material. Stable thermal property and low cost are some of its key aspects.Optimized Performance for Pipe Manufacturing

This Pipe Grade PVC Resin is formulated to meet stringent requirements for pipe production, balancing mechanical integrity and processability. With excellent bulk density and moisture content control, it enhances extrusion stability and yields high-quality, leak-resistant pipes for various applications.

Consistent Quality and Purity Standards

Sourced with meticulous attention to purity (99.9%), our PVC resin ensures minimal contamination and consistent coloration. The low ash (0.03% max) and volatile contents support exacting manufacturing operations, leading to reliable outcomes for distributors and suppliers throughout India.

FAQ's of PVC Resin Pipe Grades:

Q: How does the particle size of this PVC Resin contribute to pipe manufacturing?

A: The fine particle size, with 99% passing 250 mesh, promotes uniform dispersion in the mix and smooth flow during extrusion, resulting in pipes with consistent surface quality and mechanical strength.Q: What benefits does the low ash content provide in PVC Pipe Grade resin?

A: With an ash content of 0.03% max, the resin minimizes impurities, ensuring pipes have better structural durability and fewer defects, meeting industry standards for water and chemical transport.Q: When should distributors consider using this PVC resin for pipe production?

A: Distributors and suppliers should choose this resin for applications demanding high purity, precise particle size, and optimal plasticizer absorption-typically for potable water, drainage, or industrial piping.Q: Where is this PVC resin primarily distributed and used?

A: This pipe grade PVC Resin is widely distributed to pipe manufacturers in India, serving sectors such as construction, agriculture, and infrastructure development.Q: What is the process for using PVC Pipe Grade resin in manufacturing?

A: Manufacturers blend the powder resin with additives, then process it via extrusion or molding. The controlled bulk density (0.45-0.55 g/cm3) and low moisture content aid in consistent feed and pipe wall formation.Q: How does the K Value of 65-67 affect the final pipe properties?

A: A K Value of 65-67 offers a balance between elasticity and rigidity, resulting in pipes that are tough, impact-resistant, and suitable for high-pressure environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sodium Tripoly Phosphate (STPP) Category

Metachem Russia- Sodium Tripolyphosphate

Price 76 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

RYAN INTERNATIONAL

GST : 27ACHPM6120G1ZR

GST : 27ACHPM6120G1ZR

No. 52-D, 'Samrat', Office No:6, Ground Floor,

Sir M. V. Road, Opposite Vishal Hall, Andheri (E), Mumbai - 400069, Maharashtra, India

Phone :08045800071

|

|

RYAN INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry